Alternatives for Laminate Paper

Laminations can be used in a variety of applications, often for functional purposes, to make a sheet of paper thicker and stronger. Laminations can also be used to create a specialty product, providing a combination of paper properties to create a new category of product.

Alternatives to Laminate Paper

If the characteristics you are looking for cannot be found in an existing, market ready, single ply paper, lamination is likely your best solution. Paper machines have fixed product capabilities and the best way to expand the alternative products is to laminate paper.

There are, however, a large number of alternative types of laminations. Each different type of lamination yields a product with different properties. Finding the right type of lamination depends on both your required characteristics and your budget.

Paper to Paper

Paper to paper lamination is the most basic type of lamination. At its simplest, paper to paper lamination adheres two separate sheets of the same type of paper together, creating a single, thicker sheet of paper. The cover of a printed pamphlet, for example, is often a two-ply lamination of the same paper that is used for the interior pages.

Within paper to paper lamination, there are a number of more specialized laminations:

Within paper to paper lamination, there are a number of more specialized laminations:

- Duplexing: Duplexing is the process of adhering two different types of paper together to achieve a single paper with certain characteristics. As an example, the only way to create paper that is one color on the front and a different color on the back is to duplex those colors together. Duplexed papers are often, but not always, different colors.

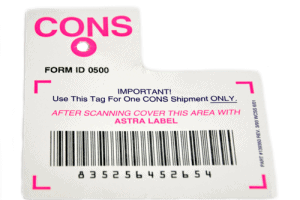

- Security Paper: Security paper laminates are paper to paper duplexes designed specifically to prevent counterfeiting and other fraudulent activity.

- Entertainment tickets, such as for concerts and sporting events, are duplexes of glossy printable paper with a thicker, often watermarked, paper. Brightly colored glues are typically used to help distinguish genuine tickets from counterfeited ones.

- Playing cards are made from a type of security paper duplexed using black glue, which prevents transparency and cheating.

- Laminated Paperboards

- Two ply coated solid bleached sulphate (SBS) paperboard offers extra thickness with coated printable surfaces on both sides.

- High strength folding carton offers coated SBS one side and natural Kraft back side for added strength in large boxes.

- Signage: Sierra Coating can laminate coated paper together using black glue, similar to playing card paper. In a retail setting, the glue prevents print show-through; banners printed on both sides can be hung in windows or near other light sources without printed text or images showing through the paper.

The challenge with paper to paper laminations is ensuring that, when making paper combinations, the finished laminations will be able to be run through the next machines in the supply chain, typically sheeting equipment, printers, and die cut machines. Sierra Coating’s experts are equipped with the experience to ensure the paper to paper products are designed to successfully process through the most demanding finished converting.

Film to Paper

Film to paper laminations can be used in a variety of applications. Films can help to protect and preserve the paper or to create a printable surface with embellishments for superior printing outcomes. As with paper to paper laminations, there are several specialized film to paper laminations to choose from, including:

- Metalized Polyester (MET-PET) Film: Metalized films, a specialty at Sierra Coating, offer a polished, glossy finish to paper and paperboard. MET-PET is ideal for high-end specialty packaging, labels, and other products due to its silver shine. Learn more about the polished look of MET-PET by downloading Sierra Coating’s eBook, Helping Brand Owners Shine: The Silver Box Advantage.

- Holographic Film to Paper: Holographic film, simply put, is MET-PET film designed with a pattern — a company logo, for instance — within it. This laminate variety is often used in packaging and food service product applications.

Additional Materials

Papers, paperboards, and films are not the only substances that can be laminated. Virtually every material has lamination potential. As long as a material is available on a roll and has some tensile strength, Sierra Coating can advise and find a method to effectively laminate it, creating a product that fits your requirements.

Papers, paperboards, and films are not the only substances that can be laminated. Virtually every material has lamination potential. As long as a material is available on a roll and has some tensile strength, Sierra Coating can advise and find a method to effectively laminate it, creating a product that fits your requirements.

Coating

Coating is a non-lamination value-added service that Sierra Coating offers. Performed either pre- or post- lamination, a coating is a chemical treatment applied to a paper or paperboard to achieve characteristics that would not have been possible otherwise. Coatings can create a food-grade barrier, allow for printing on an otherwise unprintable surface, prevent curling, and more.

Lamination Experts

Sierra Coating is committed to providing our customers with convenient, cost-effective laminates. We have the knowledge to create laminates that meet all of your project requirements, no matter what they are. Contact our team today to learn more about our custom lamination and coating solutions.