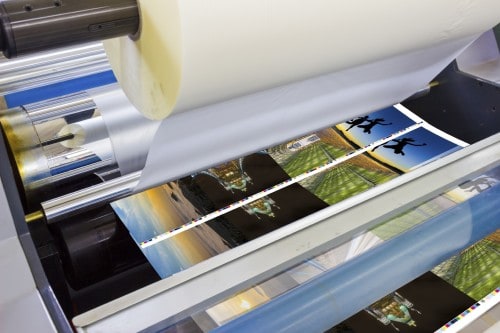

Manufacturers have been using the process of lamination globally for over a century. One of the earliest variations of this process comes from the French chemist Edouard Benedictus.

In 1903, Benedictus accidentally coated a glass flask with a plastic compound; when the flask fell to the ground, the chemist was shocked to see the glass merely shatter and not break.

This concept behind laminated glass paved the way for several innovations from industrial manufacturers—including those in the paper industry. The modern applications for paper lamination are very distinctive.

-

Enhanced product protection.

Laminations are ideal for creating a protective layer against substances such as water, oil, or grease; and is a common requirement in food and beverage packaging.

To ensure products remain sterile until they are ready for use, a vapor barrier—a thin, impermeable coating—can be used in conjunction with various laminates to keep moisture and oxygen out of the packaging.

-

Security from counterfeiting.

Paper manufacturers often use specially colored laminating adhesives as a security measure against counterfeit ticketing. When a laminate-treated ticket is torn, the unique color is clearly visible, signifying the ticket’s authenticity. These specialized tickets are resilient enough to withstand contact with water and mild bending.

This practice is used with many types of tickets, such as those for sporting events, musical performances, and even public transportation.

-

Light “Block Out” Barriers.

Some laminations are used to create an inside adhesive layer able to block the transmission of light. This “block out” coating is popular for many products that need to keep light from showing through the other side.

These products include advertisements (aisle signs or those found in store windows), trading and playing cards, photographic light boxes, and many others.

Learn About Our Paper Lamination Services

At Sierra Coating, we have over 20 years of experience providing customers with consistent, high-quality laminated paper products. In addition to being ISO, FDA, and NSF compliant, our products and services are versatile enough to meet the requirements of any application.

For more information on the extensive lamination services we offered, please contact Sierra Coating today